25 years hose making machine manufacturer

Greenland Technology,25 years flexible hose making machine manufacturer, offers competitive factory prices and overseas technical services.

Providing one stop braiding solutions, winding, braiding, cutting, crimping, assembly, air tighteness testing machines and labeling machines.

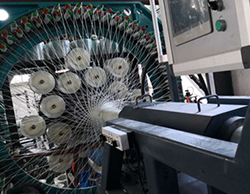

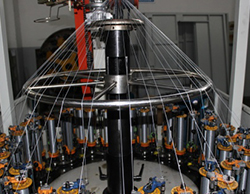

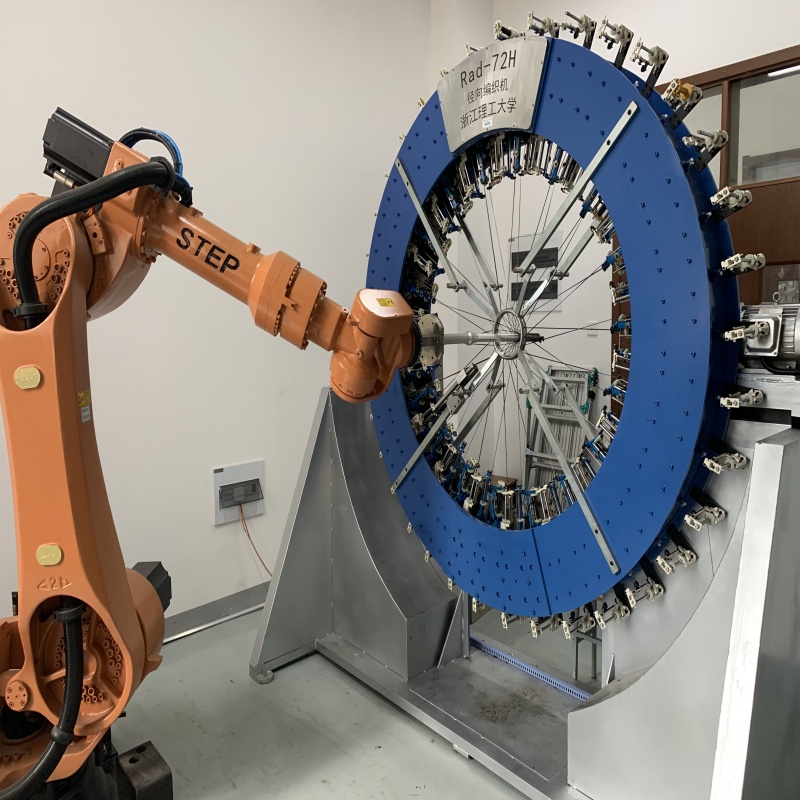

We produce double decks,multi-decks horizontal high speed braiding machines and vertical braiding machines, can braiding stainless steel wire , tensile strength wire , aluminum wire ,nylon , PE. composite material yarn.

Our automatic assembly and testing equipment for Washing machine inlet and outlet pipe, Kitchen and bathroom hose , High-pressure cleaning tube assembly, Fire equipment hose ,Sealing ring.

Widely used in Kitchen and bathroom hose, high pressure wire hose, Teflon hose, high pressure rubber hose, SS wire sleeve, air conditioning hose for car, car and motor rubber hose, sprayer rubber hose, high pressure oil hose ,sanitary hose fields and so on .Proudly serving renowned brands worldwide.

Read More

26 Jan,2025

26 Jan,2025