What Are You Looking For?

Automatic hose assembly crimping testing machine braiding machine manufacturers

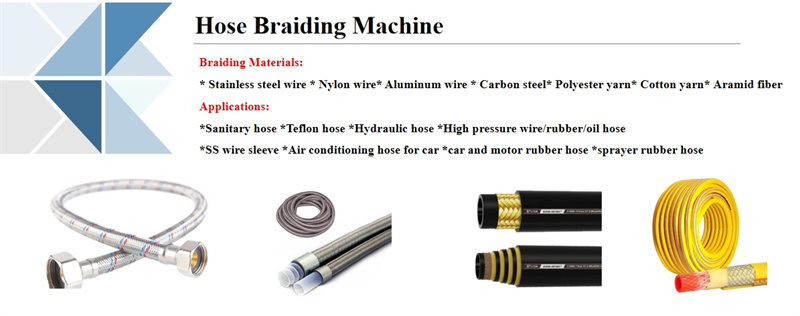

With 30 years of expertise high speed braiding machine manufacturers, our high-speed hose braiding machines are designed for precision and reliability.

Flexible hose braiding machine Widely used in producing Teflon hoses, stainless steel wire sleeves, air conditioning hoses, and sanitary hoses, these machines ensure consistent quality and high efficiency.

Name :

5 in 1 Automatic Assembly MachineCountry of origin :

ChinaPayment terms :

TT,DP,LC,PAYPALLead time :

30 daysApplications :

*Sanitary hose *Teflon hose *Hydraulic hose *SS wire sleeve *car and motor rubber hose *sprayer rubber hoseCompany type :

hose making machines manufacturerMotor Power :

8KWVoltage :

AC220V-50HZ (can be customized)Rated air pressure :

0.5MPa-0.7MPaWork efficiency :

450pcs per hourMachine size :

3200*1400*2100mmMachine weight :

850KG

High speed braiding machine manufacturers:

| carriers per deck | bobbin dimension |

| 8-96 | 80×28×277mm |

| carrier speed [RPM] | bobbin capacity |

| 25-55 | 130cm3-1320cm3 |

| Type | carrier per deck |

carrier speed [RPM] |

braiding machine power |

haul off motor power |

braiding pitch set up | carrier tension | braided hose OD |

Weight |

| BFB16L-140CFS | 16 | 55rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤16mm | 300kg |

| BFB20L_140B | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L_140B II | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140BF | 20 | 45rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤20mm | 350kg | |

| BFB20L-140CF | 20 | 44rpm(max) | 1.5KW | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤20mm | 350kg |

| BFB24L-140CFS | 24 | 42rpm(max) | 1.5KW*2 | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 580kg |

| BFB24L-140AF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140AF II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140B II | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140BF | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140CF | 24 | 42rpm(max) | 1.5KW | 0.55KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 380kg |

| BFB20L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L+24L-140CFS I | 24 | 37rpm(max) | 1.5KW*2 | 0.75Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 700kg |

| BFB24L-140CS | 24 | 37rpm(max) | 1.5KW*2 | 0.55Kw | electronic parameter set | 0.4kg-5.0kg | ≤24mm | 630kg |

| BFB24L-140D | 24 | 37rpm(max) | 1.5KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB24L-140DI | 24 | 37rpm(max) | 1.5xW | mechanical variable speed drive | 0.4kg-5.0kg | ≤24mm | 380kg | |

| BFB32L-140A | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32-140B | 32 | 28rpm(max) | 2 2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤32mm | 430kg | |

| BFB32L-140CF | 32 | 28rpm(max) | 2.2KW | 0.75KW | ectronic pararmeter set | 0.4kg-5.0kg | ≤32mm | 430kg |

| BFB36L-140AF | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140B | 36 | 29rpm(max) | 2.2KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140BF | 36 | 29rpm(max) | 2 2xw | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB36L-140CF | 36 | 29rpm(max) | 2.2KW | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤36mm | 520kg |

| BFB36L-140D | 36 | 29rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤36mm | 520kg | |

| BFB48L-140B | 48 | 25rpm(max) | 3.0KW | mechanical variable speed drive | 0.4kg-5.0kg | ≤48mm | 550kg | |

| BFB48L-140CF | 48 | 25rpm(max) | 3.0Kw | 0.75KW | electronic parameter set | 0.4kg-5.0kg | ≤48mm | 550kg |

About us: